"It's all very well saying you are going to support your supply chain with a just transition, but first, you have to get your own house in order," says Aimee Doole, Strategy, Communications and Marketing at Booth Welsh.

With carbon reduction plans, you have "to understand this in-house before you can advise clients on their strategies."

The company, Booth Welsh, provides solutions in process engineering to organisations worldwide. In recent years, the company has been on its own ESG journey, and according to Aimee, it has been quite the journey— "living and breathing our values authentically…embedding the principles of sustainability into the whole company, rather than it being the job of the tech team, or compliance team or finance team." She adds that with carbon reduction plans, you have "to understand this in-house before you can advise clients on their strategies."

But for me, three things stand out. Firstly, this company has been around for over three decades, but it works with cutting-edge technologies, including the industrial Internet of Things, that didn't exist when the firm was founded. Secondly, Booth Welsh demonstrates how focusing on the planet and people can create greater growth, leading to greater profit. Thirdly, collaboration with like-minded firms, partly via Net Zero Nation, has been an important part of its sustainability journey.

Aimee Doole on the ESG Show

So, let's look at what the company does, how it has developed and evolved as technology has changed and its approach to sustainability.

The business

Booth Welsh specialises in integrated engineering services to provide solutions:

· in process engineering,

· in process control and systems integration,

· in electrical and instrumentation design,

· in control panel design and build & installation,

· and in augmenting its services with digital technology.

The company is over 30 years old and has built a team of highly experienced people since inception.

It develops solutions across multi-disciplined engineering services with the objective to drive value for its client base.

Examples of how the above works are:

· A project it undertook for a large dairy manufacturer with data analysis saved the client £1 million by using data to predict failures.

· Supporting a pharma business applying digital twin technology to identify early design issues, saving £100,000 in design costs.

· Supporting a pharma business with remote support, applying virtual reality, saving time and money equating to £300,000.

· Supporting a client applying the Industrial Internet of Things sensors to help digital transformation, creating around 30% savings.

Disruptive technology— the response

Andy Brittan, Head of Technology and Digitisation at the company, says, "We are all engineers here." I think that is a telling point.

Booth Welsh was founded in 1989, and since then, gales of disruption have blown across industry, claiming many victims. But such disruption can be an opportunity; as the economist Joseph Schumpeter said, we also get "gales of creative destruction."

Booth Welsh, or so it seems to me, has developed the rare knack of knowing when to embrace new technology and when to work with a customer's existing asset, eking out the most from it, maybe combining it with the new.

Exploring new ideas is vital — technology changes at a breath-taking pace. But some engineers find the pace of change exciting; they want to experiment and understand when a new technology is useful. It is not technology for technology's sake; it is knowing when it is right for the customer. As Aimee told me: "It's about moving from cool to useful."

The company has pivoted multiple times, that isn't easy, but with the right people, such change can be both a joy and relevant.

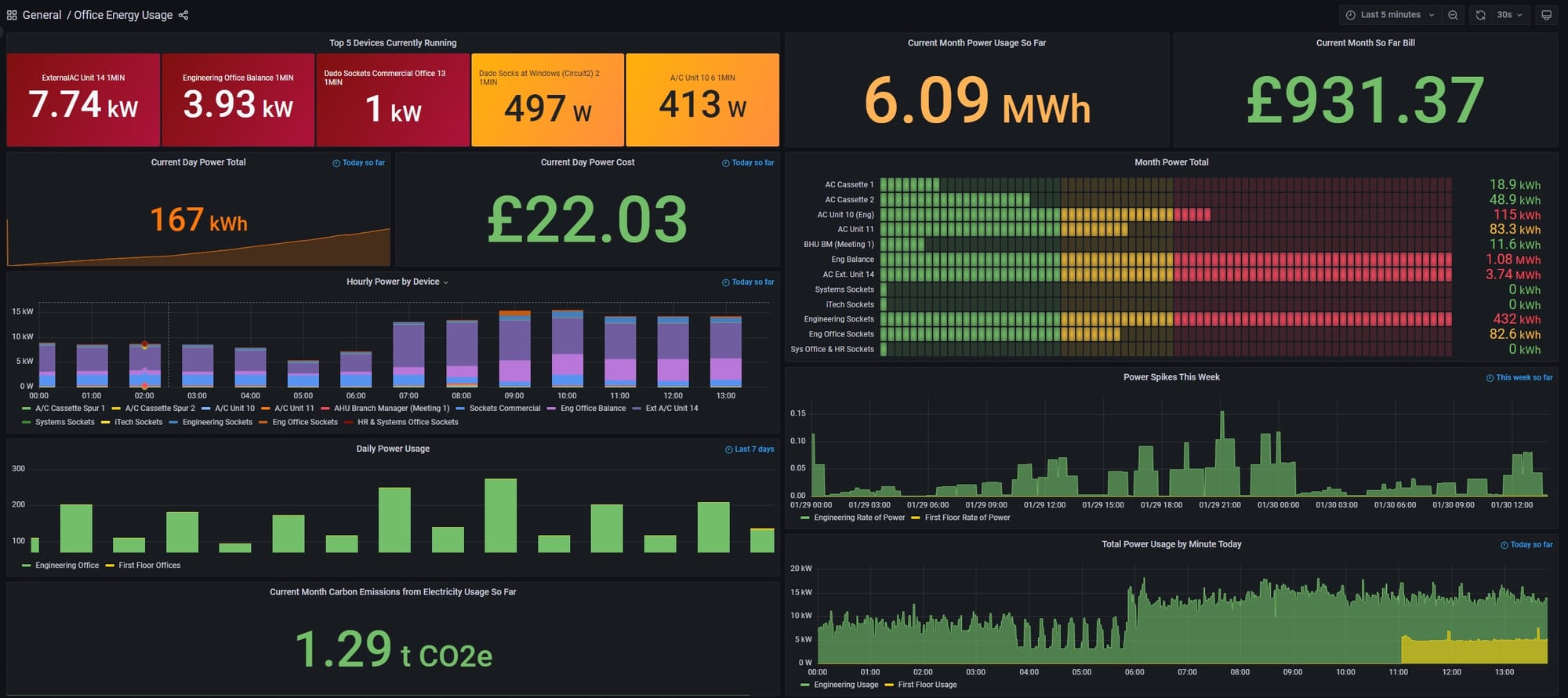

So, Booth Welsh, for example, works with the Industrial Internet of Things, enabling the collection and analysis of vital data. While some looked at the idea of the Internet of Things and asked why anyone would need a fridge connected to the Internet, Booth Welsh focused on how connecting equipment that could help make processes more efficient.

In practice, connectivity often means tagging assets within an organisation with QR codes, connecting them to a control system. The result can be 3D models, diagrams, flowcharts, in-structural videos, creating intelligent workflows.

They even employ a video game developer working on mixed and virtual reality to support training.

Take another example: Mixed and Virtual Reality. As Andy Brittan said, Booth Welsh applies these technologies: "Mixed Reality means there is less reason to send someone across the world." Instead, Mixed Reality can be applied to support an organisation on the other side of the planet from the Booth Welsh base in Scotland.

But I particularly liked Andy's example of how it has connected 100-year-old looms from a weaving firm to the Industrial Internet of Things — that is surely sustainability writ large.

People plus planet equals greater profit.

The technologies Booth Welsh works with have a multiple impact. They create efficiencies for the companies they support while saving carbon and creating social value, — serving people, the planet and the P&L.

Mixed reality, for example, is applied in training staff — sometimes working in potentially dangerous situations. It is surely safer to learn from the safety of the virtual world — for example, teaching staff about the use of glove boxes used by chemical and pharmaceutical firms.

Aimee gave me an example of applying Booth Welsh technology internally — swapping an inefficient boiler for a new system and reducing their gas bill by 80 per cent. Energy efficiency, or process efficiency, usually means a smaller carbon footprint.

Booth Welsh sums it up with the phrase Environment 4.0 — building upon industry 4.0 to create efficiency and support the environment — or planet, with no trade-off on the bottom line.

"It has been an ongoing journey," says Aimee. Cop26, held in Glasgow in 2021, was a key milestone But to improve upon anything, you have to understand what you have in the first place. To reduce your carbon footprint, you need to know what it is and be able to measure how much you are reducing it. The relationship with Net Zero Nation enabled Booth Welsh to implement carbon accounting and gain a carbon plan aligned to the UN Science Based Targets, something that is fast becoming mandatory to win contracts.

But there was another benefit — the importance of collaboration with like-minded organisations— with the support of Net Zero Nation. Aimee talks about collective insights. By working with other organisations on a similar net zero journey, she says, "we have been able to share, bring and learn a lot."

She adds that this collaboration "allowed us to develop our in-house carbon competency." And she talks about the importance of weaving the concept of

'people led' into an organisation.

Collaboration and purpose.

The idea that reducing the carbon footprint or worrying about the social impact of a business necessarily carries a high cost is a myth. Instead, creating efficiency and reducing a carbon footprint often go hand in hand. Technologies such as the Industrial Internet of Things can simultaneously help reduce costs and cut the carbon footprint; the insights brought by data can save money and even anticipate challenges before they manifest. Virtual and mixed reality can simultaneously save costs, support safety and dramatically cut carbon footprints. Booth Welsh's mission is "through collaboration, we engineer a better future."

Partially as a result of its collaboration with Net Zero Nation, Booth Welsh recently published its first impact report. These words from the CEO, Martin Welsh, summarise the opportunity of people, planet and profit well. He said: "Since our management buyout in 2008, we have been able to start embedding a People and Planet Positive set of values at the heart of our business. As such, we've established a sustainability and social value strategy that reflects our beliefs that you do not need a trade-off between addressing the environment and the value you place in your workforce and your community in order to achieve measurable results. We first referred to this as 'Environment 4.0' in 2021, and these values are now included within the new European Industry 5.0 initiative.

For more articles in this series:

Related News

Introducing The ESG Show Summit

Mar 05, 2025

Is AI really the solution?

Oct 25, 2024

ESG and the CEO

Jul 30, 2024